The company's cash operating cycle. Operational, production and financial cycles. Operating cycle: calculation formula

For effective management of an enterprise’s working capital, it is very important to monitor and be able to influence the three most important parameters that influence the need for financing:

Production cycle

The production cycle begins from the moment the company receives raw materials (or goods in the case of a trading company) from suppliers and ends with the shipment of finished products (goods) to customers.It is clear that this term is not entirely suitable for trading companies, but, nevertheless, it is already considered generally accepted, therefore it is also used for them.

An analogy can be made here with the classification of expenses. There are manufacturing expenses on the income statement. Despite its name, any company, including trading ones, can have this group of expenses.

Obviously, the shorter the production cycle of an enterprise, the better. Any company assets require financing. Therefore, the longer the company's money is in inventory, the worse it is, and vice versa.

The production cycle of an enterprise is influenced by:

Therefore, the production cycle can be reduced by reducing the inventory turnover period.

Financial cycle

The financial cycle begins from the moment of payment to suppliers of materials (goods) and ends when money is received from buyers for shipped products (goods).Obviously, the longer the financial cycle, the greater the need for working capital. Therefore, you need to try in various ways to reduce the financial cycle.

The company's financial cycle is affected by:

It is necessary to pay attention to the fact that, unlike the production financial cycle, it can also be negative. An enterprise cannot ship finished products (or goods) until it produces them (or purchases goods). Therefore, the shipment of finished products (goods) cannot be earlier than the purchase of raw materials (or goods).

As for the movement of money, it can occur at any time. If a company pays suppliers later than it receives money from customers, then the financial cycle turns out to be negative.

Operating cycle

The operating cycle is the period of time during which the company's current (current) assets make a full turnover.The company's current assets include:

Obviously, the operating cycle cannot be less than the production cycle. In most cases it exceeds it.

It is also clear that the operating cycle, like the production cycle, should be strived to be reduced, since the faster current assets turn over, the better for the company.

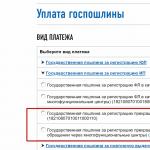

The relationship between production, financial and operating cycles

All these three cycles are interconnected (see. Rice. 1). In fact, this figure shows only one of the possible relationships.Rice. 1. The relationship between the production, financial and operating cycles

Not all companies receive material resources from suppliers without advance payment and ship their products without receiving advance payment from customers.

All possible options for the relationship between the operating, production and financial cycles are presented in table 1.

Table 1. Possible options for the relationship between the company’s operating, production and financial cycles

The eighth option is the best for the company in terms of efficient use of working capital. Indeed, in this case, the company first receives an advance payment from customers, then receives material resources from suppliers, then ships the products and only after that pays money to suppliers.

The seventh option is the worst, since in this case the company first makes an advance payment to suppliers, then obtains material resources, then ships finished products and only then receives money from customers.

Basic principles for increasing the efficiency of working capital used

These principles follow from a very obvious logic associated with the very concepts of operational, production and financial cycles.The basic principle of effective use of working capital– reduce the company’s operating cycle due to:

In turn, it is necessary to strive to reduce the production cycle by:

And the reduction of the financial cycle should occur due to:

As for the production cycle, perhaps only one of its components may not be subject to any targeted influence. We are, of course, talking about the period of turnover of work in progress, that is, the timing of production.

This parameter can sometimes be reduced only by violating the production technology. Of course, it is better not to do this, since as a result you can get low-quality products, which will ultimately affect the financial and economic condition of the company.

Although, in some cases, optimization of production processes makes it possible to reduce production times without disrupting production technology. If all the reserves for increasing work efficiency in this direction have already been discovered, then production time can only be reduced through the use of more modern equipment (and not always).

Purchasing new equipment can lead to significant investment costs. That is, due to such a decision, the company can reduce the need for working capital, but increase the need for investment.

Moreover, investment costs can be significantly greater than the savings that the company will receive by reducing the need for working capital. In some cases, a company will have to work for more than one year before the total effect of savings on working capital will cover investment costs.

In relation to the other two components of the production cycle, it can be argued that there is, as a rule, more room for maneuver.

The turnover period for inventories of raw materials and materials largely depends on the company's policy in the field of supply of basic material resources. In addition, suppliers can influence this, in particular due to how quickly they can deliver their products.

After all, a company can keep large stocks of materials in a warehouse precisely because suppliers cannot quickly provide the company with the necessary resources. In some cases, it is possible to find other suppliers with whom it is more profitable for the company to work in this regard.

In fact, of course, the selection of suppliers should be made on the basis of a comprehensive analysis, including an assessment of other important parameters, in particular payment terms.

The company can also influence the turnover period of finished products (or goods) by improving the quality of sales planning, as well as the efficiency of the sales process itself.

Large inventories of finished products (goods) may be a consequence of poor quality of the sales planning process. In this case, the company hedges its bets and keeps significant inventories in its warehouse.

Increasing the efficiency of the sales process can also have a positive effect on reducing the turnover period of finished products. The faster a company can sell its products, the shorter its turnover period.

In terms of shortening the company's financial cycle, the main efforts should be directed toward reducing the receivables turnover period as much as possible and increasing the accounts payable turnover period. Simply put, you need to strive to ensure that money from customers arrives as early as possible, and payments to suppliers are made as late as possible.

It may be necessary to make some concessions to customers to reduce accounts receivable turnover. For example, a company can provide its customers with discounts for reducing payment terms.

Conversely, to increase accounts payable turnover, it may be necessary to purchase resources from suppliers at less favorable prices, but with deferred payment.

So, to improve the efficiency of working capital management, an enterprise needs to clearly monitor its operational, production and financial cycles. We need to learn to find opportunities to reduce all these cycles.

Note: the topic of this article is discussed in more detail at the workshop

the duration of the operating cycle increased by 65 days, which is a negative fact, since it leads to an increase in the need for working capital to finance current activities, which in turn leads to additional immobilization of funds in inventories and means of payment.

Analyzing the business activity of OJSC "Uralneftegazstroy" for 2008, the following conclusions can be drawn:

the turnover ratio of current assets decreased by 4.97%, which is a positive fact, since for each ruble of current assets at the end of the reporting period there was 13 kopecks more sales revenue than at the beginning of the period;

the duration of turnover of current assets increased by 19 days, i.e., funds invested in current assets were returned at the end of the reporting period slower by an average of 19 days, which is a negative fact;

The duration of receivables turnover increased by 5 days. This fact indicates a decrease in the level of accounts receivable management at the end of the reporting period, i.e. funds from debtors for oil and gas pipelines were received on credit 5 days slower;

the duration of inventory turnover increased by 1 day, thus, inventories at the beginning and end of the reporting period were used with the same intensity;

the accounts payable turnover ratio decreased by 4.97%, i.e., for each ruble of accounts payable at the end of the reporting period there was 11 kopecks less in sales revenue than at the beginning of the period. The company increased the volume of purchases of raw materials and supplies on credit;

The duration of accounts payable turnover increased by 9 days. This fact indicates that the enterprise is slowing down its settlements with creditors, which, on the one hand, can be considered as a positive fact, since the enterprise receives at its disposal an additional source for the advance of working capital, on the other hand, it is considered as a negative fact associated with a decrease in business enterprise reputation;

the duration of the operating cycle increased by 6 days, which is a negative fact, since it leads to an increase in the need for working capital to finance current activities, which in turn leads to additional immobilization of funds in inventories and means of payment.

the duration of the financial cycle increased by 3 days, which is also a negative fact, since it slows down the process of reinvesting profits in the current activities of the enterprise.

Analyzing the business activity of OJSC "Uralneftegazstroy" for 2009, the following conclusions can be drawn:

the turnover ratio of current assets increased by 6.94%, which is a negative fact, since for each ruble of current assets at the end of the reporting period there was 5 kopecks less in sales revenue than at the beginning of the period;

the duration of turnover of current assets decreased by 29 days, i.e., funds invested in current assets were returned at the end of the reporting period faster by an average of 29 days, which is a positive fact;

The duration of receivables turnover decreased by 9 days. This fact indicates an increase in the level of accounts receivable management at the end of the reporting period, i.e. funds from debtors for oil and gas pipelines were received on credit 5 days faster;

the duration of inventory turnover decreased by 2 days, thus, inventories at the beginning and end of the reporting period were used with almost the same level of intensification;

the accounts payable turnover ratio increased by 6.94%, that is, for each ruble of accounts payable at the end of the reporting period there was 13 kopecks more sales revenue than at the beginning of the period;

The duration of accounts payable turnover decreased by 13 days. This fact indicates that the company is accelerating its settlements with creditors;

the duration of the operating cycle decreased by 11 days, which is a positive fact, since it leads to a reduction in the need for working capital to finance current activities, which in turn leads to the release of cash from inventories and means of payment. This fact means an increase in the absolute liquidity of the enterprise, thereby ensuring an increase in the absolute value of covering urgent liabilities;

Assessment of business reputation of management companies

For many years, it has been believed that business reputation has a great influence on the activities of a company, can significantly increase the value of an enterprise, and also generate additional profits...

Economic importance of tourism statistics, history, trends

international tourism global Tomsk Tourism as a social phenomenon has a long and rich history going back centuries. Man throughout his entire evolution has been characterized by the desire...

Assessing the effectiveness of a commercial organization

The problem of efficiency occupies a leading place among the totality of problems facing society. It has concerned economic science and economic practice for many centuries. Special...

Duration of operating activities (operating cycle, duration of operating cycle), in days

Defined as: Duration of inventory turnover + Duration of receivables turnover

Inventory turnover (in days)= (Inventory + VAT) / Cost for the year

Turnover of funds in settlements (in days)= Short-term receivables/annual revenue

The operating cycle shows the time for which a company's resources, including those received in the form of deferred payments, trade or merchandise loans (accounts payable), are frozen in inventories and receivables.

The operating cycle is considered before calculation

The financial analysis:

- Let's consider the business activity (turnover) ratios: Working capital turnover ratio; Equity turnover ratio; Asset turnover ratio; Equity turnover ratio; Inventory turnover ratio; Ratio…

- Financial cycle in days = operating cycle - accounts payable turnover period. Accounts payable turnover period (in days) = Cost per year/(Short-term loans + Accounts payable to suppliers...

- To calculate the net cycle in days, we can recommend using the following table: Name 2011 2012 2013 Inventory turnover Accounts receivable turnover Turnover of other current...

- To analyze business activity indicators (in days), we can recommend compiling a table like this Name 2011 2012 2013 Return on assets Return on fixed assets (capital productivity) Turnover of current assets...

- On the website you can perform two tasks: Firstly, you can conduct financial analysis online And secondly, below on this page all types of analysis are described that...

- Financial stability is determined, firstly, with the help of coefficients, and secondly, with the help of a three-component indicator of financial stability. First, I will give a list of coefficients: Equity ratio, Agility coefficient...

- Model O.P. Zaitseva to assess the risk of bankruptcy of an enterprise has the form: K = 0.25X1 + 0.1X2 + 0.2X3 + 0.25X4 + 0.1X5 + 0.1X6 where: X1 - Buy...

- Asset structure. The assets of the enterprise are divided into 2 large groups: non-current assets (immobilized funds), the service life of which is more than 12 months; current assets (mobile assets), service life...

- On this page you can calculate the effect of operating leverage on the income statement. It must be taken into account that the assessment will be approximate, because there is no division in the reporting...

- French economists J. Conan and M. Golder, using the Altman method, built their model. Conan-Golder formula: Z = -0.16X1 - 0.22X2 + 0.87X3 + 0.10X4 - 0.24X5…

The operating cycle is an integral part of the enterprise's functioning process. What is he? What intervals are included in it? How to calculate the optimal operating cycle time? These, as well as a number of other issues, will be discussed in this article using numerous examples.

general information

Any industrial enterprise that operates has its own operating cycle. What is he? This designation is used for the period of time during which material and production inventories (raw materials, tools) are purchased, finished goods are created, which are sold on credit or for cash. After which the receivables are repaid. This is all the operating cycle of an enterprise. It is used to show the period of time during which the current assets of a business organization are fully utilized. Every entrepreneur or specialist should know how the operational and financial production cycle are interconnected. Why?

General scheme of work

Let's look at how everything happens from the very beginning. So, it all starts with the purchase of raw materials. When it enters the production line, the operating cycle begins. It ends when funds are received from the buyer of the product. Conventionally, two options for its implementation can be considered:

I. Production cycle and receivables turnover period. In this case, the first part continues from the moment the processing of raw materials begins until the sale of finished products (but this is not the same as receiving money, be careful). Materials are processed, semi-finished products are made - and so on until the final product is reached. After an agreement for the sale of finished products has been concluded and they have been shipped, the receivables turnover period begins. It ends the moment the buyer transfers funds (or the last payment, if he took out a loan).

II. Accounts payable turnover period and financial cycle. The first part in this case continues until the received raw materials are paid for. Next will be the financial cycle until the client pays for the manufactured products.

You can look at the process from two points of view. But one thing remains unchanged - that the operating cycle is completed in both cases. Although there are slightly different views on its components. Let's take a look at them too.

Components

There are also slightly different views. The option below is in many ways similar to the previous one. And according to it, the operating cycle period looks like this:

I. Inventory turnover. This is the average time (calculated in days) that is needed to transform raw materials into finished products, as well as sell them. It begins when the materials arrive at the warehouse and ends as soon as the goods are shipped to the buyer.

II. Accounts receivable turnover. This is the average time it takes a customer to pay the full amount for an item that was sold on credit.

III. Accounts payable turnover. This is the average time that a company needs to pay off loans taken out for the purchase of material and production supplies.

The duration of the operating cycle is a unique value for each individual organization.

About current assets

They are the most mobile part of the organization's assets. These objects can be used in one or several operating cycles (but only within a short calendar period of the year). At the same time, they are considered mobile assets of the organization, that is, those that are either cash or can be quickly converted into cash. Current assets have three stages of their life:

I. Procurement. Initially, they are transformed from a monetary form into a production form (tools and raw materials).

II. Creation. At this stage, with the help of the tools used, the raw materials take not a production, but a commodity form.

III. Implementation. Current assets are transformed from commodity form to monetary form.

That's all. This concludes the operating cycle, and a new one can begin.

A little math

Let's talk about the operating cycle using some math. Do not rush to close the page, because we will pay attention only to the necessary points, because calculating the operating cycle allows you to avoid unnecessary losses and miscalculations when carrying out activities. So:

I. Residence time of raw materials, as well as materials in the warehouse: B = (SZ / GMZ) * 365. What does this formula mean? Here SZ is the cost of inventories of materials and raw materials, while GMZ is the annual material costs. 365 is the total number of days. In a leap year there will be 366 of them, don't forget about it.

II. Production process time: PP = (SZNP / (SP * K)) * 365. SZNP is the cost of work-in-process inventory. SP - the cost of products that were sold. K is the cost increase coefficient, which characterizes the ratio of the cost of unfinished production to the amount of money needed to create a finished product.

Features of financial cycles

Initially, it should be noted that the theory does not simultaneously take into account the presence of both accounts payable and advances already issued. What to do in this case? If the goal is to conduct an analysis, then they usually compare advances issued with accounts payable, as well as amounts of money received with accounts receivable. And based on the dominant indicator, the final assessment of the financial cycle is carried out.

There is one point here. The shorter the cycle duration, the less the organization is provided with current assets. And accordingly, it can be more risky. And the opposite point. With a significant cycle length, the organization’s need for source(s) of financing increases, along with its appetite.

Let's look at a small example with wholesale suppliers. In this case, a significant cycle leads to a loss of margin due to the need to pay interest on loans attracted to create receivables. In other words, one can observe a contradiction between sustainability and efficiency.

Operating cycle optimization

Alas, it is impossible to control everything in this world. Changes in the supply scheme, payment terms and other unpleasant aspects can be considered as a situation in which the organization loses its market position and a threat to continuous operations begins to appear due to the need for financial resources. How can you make progress:

I. To do this, it is necessary to work on reducing the time component of the cycle (especially its financial part). You can concentrate on the process of purchasing raw materials, production, improve sales and reduce the number of days (weeks, months) when finished products are in warehouses.

II. Reduce repayment periods for receivables, tighten credit policy, but only if market conditions allow this.

III. Maximize loan repayment time by agreeing with suppliers on deferred payments.

Dangers of Optimization

Keep in mind that by extending the operating cycle, sustainability will be achieved while profit margins and overall efficiency will decline. If you shorten it, you can quickly and earn a lot. But at the same time there will be a high risk of burning out. At the same time, attempts to change the state of affairs will show the organization’s position in the market. So, if they require an advance payment, then this indicates that they do not believe in the company and have doubts. If you are ready to give an advance, it means that you are interested in interaction.

If you are interested in building an organization with effective management and financial stability, then you need to take care of the absence of significant prepayments, as well as the balance of accounts payable and receivable. And here, too, one interesting and specific point arises.

The paradox of an effective organization

Companies and businesses that have everything set up, that run smoothly, have significant power and are purposefully reducing their cycle times. For this purpose, prepayment and accounts payable instruments are widely used. But all this is organized in such a way that financial stability remains at a fairly high level.

By the way, we previously talked about the operational and production cycle as its component. When developing an implementation program, it is necessary to take into account not only the theoretical efficiency of using working capital, but also the objective processes that take place in the enterprise. Unfortunately, as a rule, they only increase the work time. At the same time, the asset turnover ratio decreases. And to compensate for the decline, we have to increase the margin. But this can already lead to an increase in return on capital, which in itself is good.

Conclusion

As you can see, the operating cycle can be called the basic general point in the work of any industrial organization. The success of the enterprise largely depends on how well it is designed and implemented. Moreover, if a successful configuration is found, this does not mean that everything is already good, and improvement activities can be curtailed. It is always necessary to test the situation so that if the situation changes, you can immediately respond with all necessary actions. How can one not recall the wonderful law of evolutionary selection formed by Charles Darwin: “It is not the strongest that survives, but the fittest.” And although these words were formed for biology, they are no less relevant in economics.

- Solovyova Polina Andreevna, student

- St. Petersburg State Economic University

- DURATION

- OPERATING CYCLE

- PRODUCTION CYCLE

- FINANCIAL CYCLE

- WORKING CAPITAL

Any enterprise goes through an operating cycle, which includes two more important components: the inventory turnover cycle and the cash turnover cycle. The most important indicator of effective management of working capital is the duration of these cycles.

- Improving the conditions for stimulating environmental activities of the enterprise

- Assessment of the financial condition of an enterprise and ways to prevent insolvency

- Approaches to the optimal choice of professional development path

Regulation of the use of working capital of an enterprise is associated with certain characteristic features of the formation of its operating cycle, which in turn includes two other cycles: production and financial.

The duration of the cycles described above is the most important indicator of the effectiveness of current asset management.

Operating cycle- the time stage from the acquisition of raw materials to covering the invoice for the finished product.

Production cycle- the time stage from the purchase of raw materials/materials to the acceptance of finished products that were produced from these raw materials/materials.

Financial cycle, which is also called the cash turnover cycle - the time stage from paying money for raw materials, which in turn is called paying off accounts payable, to receiving money for sold products (paying off accounts receivable).

The duration of the operating cycle shows the turnover of the enterprise's working capital, and shows the number of days for the exchange of funds for raw materials/materials to occur. This indicator is considered one of the main indicators of the effectiveness of working capital regulation.

To calculate this indicator, you need to sum up the accounts receivable turnover period, the inventory and costs turnover period, the accounts receivable turnover ratio and the inventory and costs turnover ratio.

Due to an increase in the duration of the operating cycle, the need for working capital increases, and a decrease, on the contrary, is a positive indicator, because as a result this need decreases.

This need may occur due to the following factors:

- Reducing production process time

- Accelerating receivables turnover

- Slowdown in accounts payable turnover

Calculating the duration of the production cycle of an enterprise helps to estimate the time costs for the production of goods.

To calculate this indicator, you need to sum up the duration of the production cycle, the duration of technological processing, the duration of technological maintenance and the duration of breaks due to the operating hours of the enterprise

Calculation of the duration of the cash turnover cycle characterizes the number of days between accounts payable and accounts receivable.

To calculate the duration of this cycle, you need to sum up the duration of the financial cycle, the duration of the inventory turnover, the duration of the turnover, accounts receivable and the duration of the accounts payable turnover.

Basic principles for increasing the efficiency of working capital used

In order to increase the efficiency of current assets, it is necessary to ensure that the company's operating cycle is reduced by reducing the production cycle and reducing the financial cycle.

The production cycle of the enterprise is reduced:

1. Due to the decline in the turnover period of raw materials and supplies.

Otherwise, either depletion of warehouse stocks occurs, which in turn leads to interruptions in this cycle, or, on the contrary, excess stocks accumulate, the efficiency of warehouse management decreases, and unusable materials accumulate in the warehouse. After all, a company can keep large stocks of materials in a warehouse precisely because suppliers cannot quickly provide the company with the necessary resources.

Also, this period largely depends on the company’s policy in the field of supply of basic material resources.

2. Due to the reduction in the turnover period of work in progress

This is one of the most difficult parameters to target, because it can be reduced mainly by disrupting the technological process of production, and this can affect the quality and financial component of the company.

Sometimes, in order to reduce this figure, a company can purchase new modern equipment, which, of course, will not be without consequences.

This will entail a large loss of funds for the company. That is, in order to reduce the need for current assets, the company will have to increase financial ones.

It is important to note that investment costs may be significantly greater than the savings that the company will receive by reducing the need for current assets. In some cases, the company will be forced to work for more than one year before the total effect of savings on current assets covers investment costs.

3. Due to a decrease in the turnover period of finished products/goods.

The company can influence this parameter by improving the quality of sales planning, as well as the efficiency of the sales process itself.

Large inventories of finished goods/goods may be a consequence of poor quality of the sales planning process. In this case, the company hedges its bets and keeps significant inventories in its warehouse.

Increasing the efficiency of the sales process can also have a positive effect on reducing the turnover period of finished products. The faster a company can sell its products, the shorter its turnover period.

The company's financial cycle should occur through:

- reducing the receivables turnover period;

- increasing the period of accounts payable.

It is important to resolve the issue not only of reducing accounts receivable, but also of balancing it with accounts payable.

It is possible that in order to reduce the turnover of accounts receivable, the company will be forced to make concessions to customers, and in order to increase the turnover of accounts payable, it may be necessary to purchase resources from suppliers at less favorable prices, but with deferred payment.

So, to improve the efficiency of working capital management, an enterprise needs to clearly monitor its operational, production and financial cycles. We need to learn to find opportunities to reduce all these cycles.

Figure 1. Cycle relationships

Bibliography

- Blagikh I.A. Management of the production cycle of an enterprise // Problems of modern economics. – 2010. – P. 97-100.

- Bocharov V.V., Moldovan A.A., Rumyantseva T.V., Skorokhod A.Yu., Tereladze D.I., Fedorova S.V., Shvedova N.Yu., Yuryev S.V., Chernenko V. .A., Fedorov K.I. Financial Management // Textbook and workshop for academic undergraduates, St. Petersburg, 2016.

- Gerasimenko A. Financial management. Course for managers and beginners. / A. Gerasimenko. – M.: Alpina Publisher, 2017. – 482 p.

- Kandrashina, E.A. Financial management: Textbook / E.A. Kandrashina. - M.: Dashkov and K, 2015. - 220 p.

- Naydenova, R.I. Financial management: textbook / R.I. Naydenova, A.F. Vinokhodova. – Moscow: Knorus, 2009. – 208 p.

- Management of financial activities of enterprises (organizations): textbook / V.I. Berezhnoy [and others] – Moscow: Finance and Statistics; INFRA-M, 2011. – 336 p.